-

Notifications

You must be signed in to change notification settings - Fork 3

FloDar Updates

Author: Dexter Carpenter

- Re-did the CAD file for Transducer Casing

- Casing is for 3/4" PVC Pipe

- CAD File is Easily Modifiable

Show More

We wanted to increase the flow rate through the pipe, so we decreased the diameter to the smallest feasible. The smallest we found that still worked with the transducers that were are currently using was 3/4". The transducer spec sheet (see our Wiki) rates the diameter of the pipe to be between 15mm and 200mm (0.590551" to 7.87402"). The Transducer needs to have decent contact with the pipe for at least 13.5mm (0.5314961"). For pipes with small diameters, in order to get closer to the 13.5mm we would have to create a flat surface on the pipe via milling a part of it flat so the transducer could have better contact and get a more accurate reading. It is possible to have the transducer contact the full 13.5mm on a 1/2" pipe, however doing so leaves only a few thousandths of the pipe's wall felt, and so we went with a more comfortable 50 thousandths with a 3/4" pipe.

In design, the casing is much the same as the pervious version as seen below. I re-did the CAD entirely since it was easier for me than modifying the already existing design. Some key differences are obviously the pipe diameter, and the distance between the transducers (currently a work in progress). Most everything else is the same or similar.

Author: Andrew Walker

- Learning from Field Tests

- Update Hypnos Timing Software

- Running Tests to Understand Sensing Errors

Show More

After receiving the data from the field, there appeared to be two problems: 1) The recorded timing was off as well as the timing intervals & 2) The USFM was not reporting the flow correctly. (Figure 1) To replicate the errors shown in the field, an in lab test was run for a few hours. (Figure 2) It appeared that the timing was correct but that inaccurate flow was recorded for odd periods of time. For diagnosis of the first problem, it was found that the software for the Hypnos was not completely up to date. This was a rather simple fix and after working with Martin of the SmartRock Project, the timing was fixed. Another test was run for a full battery cycle to see if the patterns of inaccuracy became more regular over a longer period of time. However, the test showed that it was not until the the very end of the battery's life that the inaccuracies occurred. (Figure 3) It appears that keeping the battery above a certain level is necessary for proper data recording, something we hope the solar system we are planning to implement will remedy.

Author: Andrew Walker

- Accuracy vs. Flow Rate Experiment

Show More

To ensure the Ultrasonic Flowmeter selected for this system would provide accurate results, an experiment was devised to test the percent error in relation to the flow rate within the Calibration System mentioned below. The sensor's technical manual describes a limit to the accuracy associated with low flows, which was also seen in the experiment. However, the experiment also showed that as the flow rate increased the error rate decreased for most trials. Because mean error for the error rate increased between the final two flow settings, the experiment may need to be conducted again with higher flows to see if the error rate is parabolic or if the error rate truly shows a exponential approaching zero.

Testing Methodology:

- Turn on the pump at 20% of maximum flow rate

- Wait until all bubbles and air gaps have been removed from system

- If some gaps will not leave the system, turn the flow rate up to 40% until they leave and then turn back down to 20%

- Place your 500mL volumetric measuring equipment into the collection basin

- Turn on USFM

- Reset your stopwatch to zero

- With one hand, place outflow tube over your 500mL volumetric measuring equipment, starting the timer immediately

- Wait until 500mL has been reached then immediately stop the stopwatch

- Record trial

- Look at reading on USFM, record trial

- Turn off USFM

- Empty 500mL volumetric measuring equipment

- Repeat steps 3-11 until you have at least 5 trials for flow rate

- Repeat steps 3-12 for 30%, 40%, 50%, & 60%

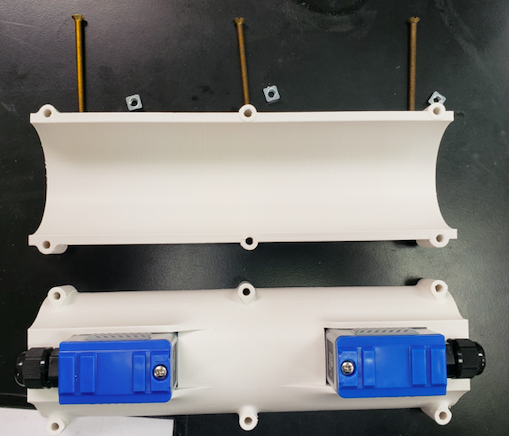

Author: Andrew Walker

- New Lab Calibration System

Show More

This section contains the removable & replaceable PVC housing for both the thermocouple and turbidity section. The unions at both ends allows for easy access to both components. The turbidity sensor is highly dependent on a clear pathway from one end to another for accurate reading. Because buildup can happen overtime, the user will be able to clear any debris if needed or a new section can be crated to take the place of a disfuctional piece.

This section connects the other end of the ultrasonic flowmeter section. This allows for easy calibration and creation for each new kit. With all preliminary testing complete, both sections can be removed and given to researchers to implement in the field. Both sides make it easy to insert in the field or reinsert in the lab system for any troubleshooting.

This is the whole lab system piping configuration. Both the left and right ends contain nozzles, the left acting as inlet and the right acting as outlet. These will stay in the lab and allow for efficient testing and calibration of the system.

Author: Andrew Walker

- Currently testing the sensors in the Lab

Show More

I have been testing the completed board and hardware configuration for a few weeks now. We are running into some issues with both the ultrasonic flowmeter and the turbidity sensor. We are hoping that creating a lab experiment that is more reflective of the current field use will increase the accuracy of the flowmeter, but for now the sensor is reporting values far too low. When the pump is on, bubbles and turbulence form in the fluid and may be the primary cause for inaccuracies. We will not know until we test, so we are hoping to make changes quickly.

The turbidity sensor has many problems associated with it at the moment. We are hoping to address these through collaboration between other OPEnS Lab members as it is in multiple projects. For now, the sensor can only indicate qualitative differences accurately, all quantitative measurements varying from one day to another. This will be an ongoing effort and we will do out best to update you as we make progress.

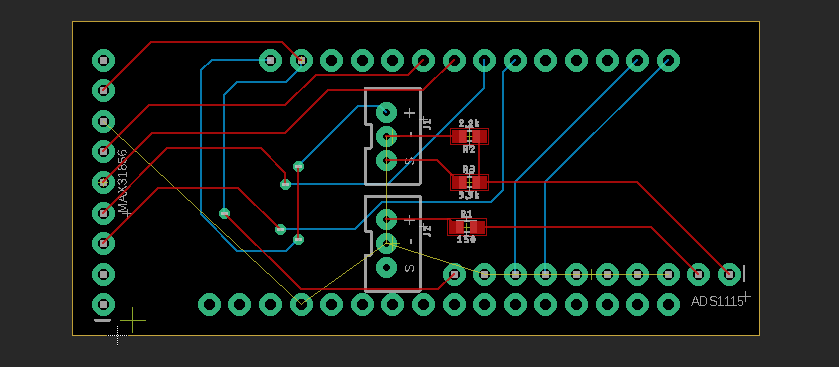

Author: Andrew Walker

- Schematic for the PCB made and sent in for validation.

Show More

I think I have finally finished a completely integrated board for the FloDar project. It is currently being critiqued by the Chet and Cara, but it was a quite fulfilling project so far. We hope to know soon if it is good enough to get printed, populated, and implemented in the testing phase. Another large step toward finishing the first prototype of the project, but still many finishing touches to go!

Author: Andrew Walker

- Machined inserts for the thermocouple and turbidity sensor.

Show More

Hadi and Bradley worked in the OPEnS Machine Shop to created a new pipe with the turbidity and thermocouple sensors inserted and in contact with the water. Though it took two tries - the first pipe breaking due to the stress of the leveling process - the product turned out great and is ready to start testing! It has shown to be be water proof, now for accurate sensor measurements.

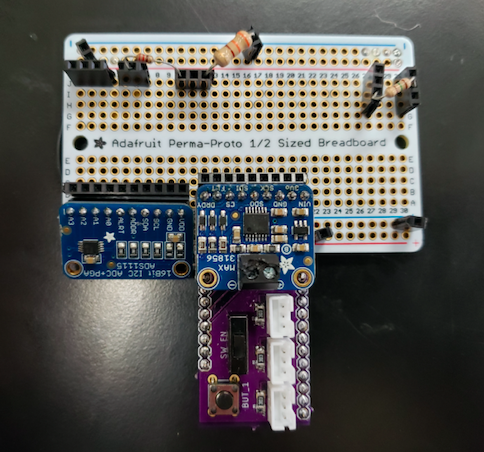

Author: Andrew Walker

- Created a functioning protoboard circuit for testing.

Show More

We have been working to make a protoboard of the circuit we will be using. The breadboard was a bit difficult to handle! Hopefully we will be able to convert this board to a proper PCB soon so that we can begin working towards a final prototype.

Author: Andrew Walker

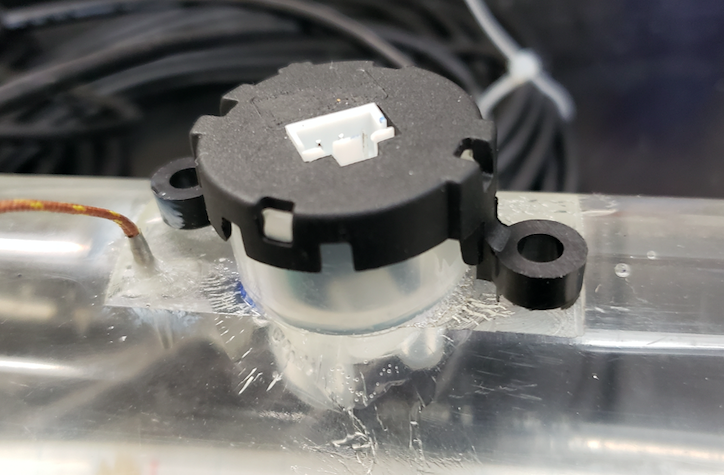

- 3D printed a holder for the transducers to easy installation process.

Show More

Hadi has created a great print to hold our flowmeter transducers. Installing the transducers has been a pain due to the awkward curve of the pipe and easy slippage. With the new compartments the transducers will be held in place while they are strapped down and set the exact distance apart thanks to the plastic spacing between them.

Author: Andrew Walker

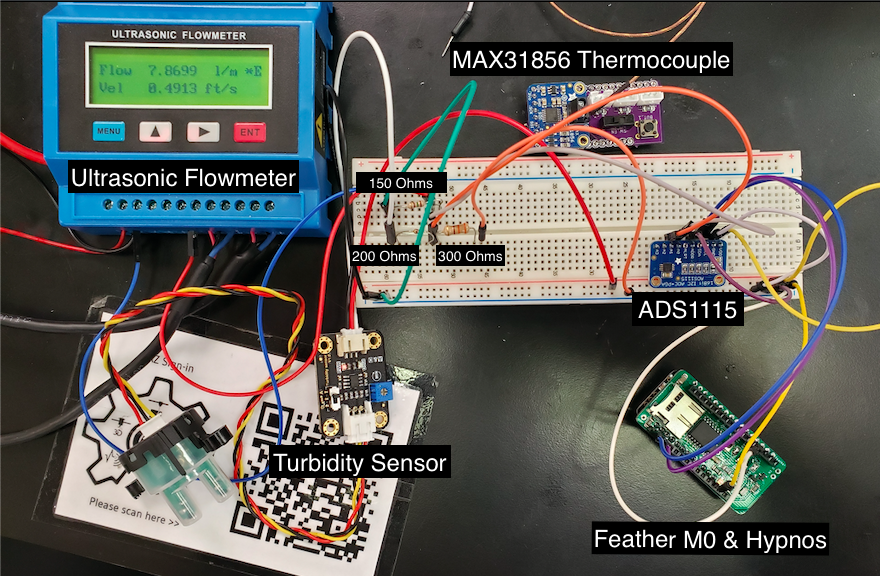

- Created most of the bread board circuit necessary to power all components and transmit them to the ADS1115.

Show More

We are working on completing the necessary circuitry for the FloDar computing. So far we have implemented a 150Ohm resistor to convert the current analog from the flowmeter to voltage, implemented a voltage divider to step down the 5V from the turbidity sensor to 3V, and sending both signals to a 16 bit ADC for more accurate measurements.

- Project Planning

- Prototyping

- Synthesis

- Lab Testing

- Field Testing

- Finalization/Production

- Poster/Presentation

- Publication

- CRES

- Dendrometer

- Djinn

- eDNA Sampler

- eGreenhouse

- Evaporometer

- FloDar

- HyperRail

- Hypnos

- Isotopic Sampler

- Lilypad

- Loom

- Micro-Aggregating Sewer Sampler

- Mooraca

- OPEnSampler

- Pied Piper

- Rag Guard

- Rain Gauge Calibrator

- RainSavor

- RFID Moisture

- Sap Flow Meter

- SitkaNet

- Slide Sentinel

- Smart Rock

- Spool

- WeatherChimes

- Weed Warden

- Wisp

- Archived Project Blogs