Releases: prusa3d/PrusaSlicer

PrusaSlicer 2.6.0-beta1

Summary

This is the first beta release of PrusaSlicer 2.6.0, mostly fixing bugs found in the previous alphas. See the release logs of 2.6.0-alpha2, 2.6.0-alpha3, 2.6.0-alpha4, 2.6.0-alpha5, and 2.6.0-alpha6. for the complete list of changes with respect to 2.5.2.

With this release, PrusaSlicer not only brings fixes but also introduces several noteworthy improvements to existing features. Highlighting the most significant enhancements, the Cut tool has been upgraded to provide increased power and functionality, Organic supports have undergone improvements to enhance stability and reliability, and modifications have been made to improve compatibility presets for multitool printers.

To let you enjoy the beta without worries, the beta builds save their profiles into the PrusaSlicer-beta directory, so you may use the beta side by side with the current release without ruining your production configuration. When you first run the beta, it will search for all configurations produced by alpha or final versions and offer to create a copy of the latest one.

Upgrades of the Cut Tool for selective object splits #9472, #9577, #9922,

The improved Cut tool now offers more flexibility by allowing users to selectively select parts of the object which should not be cut. Selection and deselection of the parts can be controlled with the right mouse button. Note that when some parts are selected, PrusaSlicer will always generate two separate objects, the option to leave everything as parts of one object is not available.

Changes in modification of compatibility of presets

When using a Multitool printer (with 'single_extruder_multi_material' turned off), PrusaSlicer now filters filament presets and presents the user with only the appropriate filaments based on the compatible printers conditions ('compatible_printers_condition') for each individual extruder. This change also introduces a new combobox in the Filament settings, simplifying the listing of extruders.

Other improvements with respect to 2.6.0-alpha6

- Embossed text objects can now be edited in Simple mode.

- When using MainSail/Fluidd print host, PrusaSlicer now uses Moonraker API, without relying on OctoPrint compatibility mode being enabled.

- A new ‘Hide/Show Custom G-Code’ button was added to the G-Code preview. The range of color scale in the legend is possible to visualize without the effect of the purge line. The button is available only for parameters where it is relevant (Width and Volumetric flow rate) #10259

- Improved error reporting when the last layer exceeds the maximum build volume height due to variable layer height. The name of the object violating print height is reported. Improvement is related to original issues. #9467 #9519 #9646

- macOS specific: Fixed performance issue with the G-Code viewer when travels were enabled.

- Added 'Zoom to mouse cursor' by Shift+Mouse wheel. Thanks to @LiZ-Li-BBL

- Thumbnails generated to G-code now use the same colors as in the 3D view. #4577

- The slicer now includes an improved algorithm for overhang speed slowdown and avoiding curled filament. A new and tuned estimation method is applied for the curled height of the filament. The estimated curling now affects the slowdown of overhang speed on external perimeters and also on internal ones. #9756. The new enhancement should significantly improve surface quality and prevent artifacts, without slowing down internal perimeters unnecessarily.

- After slicing an object with negative volumes in SLA mode, users now have the ability to toggle the visualization on or off, allowing for better control over the final geometry in the 3D editor. This convenient new button for switching between visualizations is located adjacent to the object, facilitating an intuitive user experience.

- New ensuring addresses the occasional occurrence of local zig-zag patterns that were generated in the ensuring perimeters. It detects segments with short movements that cause vibrations and can reduce surface quality, and fixes them. #9970

- Improvement of Organic supports by preventing collisions between the main object and its own support branches. Note that the collision issue between different objects and their support branches remains unresolved. #10247

- The bottom interfaces of Organic supports have been fixed and enabled, providing enhanced stability when positioned on the model's body. #9512

- The user now has control over the utilization of either one or two perimeters for Organic supports using the

support_tree_branch_diameter_double_wallparameter. #10304

Improvements in bridges over internal infill

- Improved the algorithm so it does not generate extremely long bridges when the layer below is very sparse. #10222

- PrusaSlicer now detects areas where internal bridges require anchoring to perimeters and enhances it by adding an extra ensuring line in the previous layer. This addition provides support and enhances structural stability for the bridges.

- Furthermore, PrusaSlicer has improved the handling of internal bridges when using Lightning infill. It expands the Lightning infill around bridged surfaces, ensuring improved anchoring for a greater number of bridges.

Bugs fixed with respect to 2.6.0-alpha6

- Fixed crash at startup of PrusaSlicer when any of the SVG files used as icons in dialogs is renamed or removed.

- Fix of Undo-Redo mainly for Emboss text tool. Undo-Redo will not add new parts after the text edit is closed.

- Fixed crash in SLA, when an instance of the object is selected after slice.

- Resolved the issue where the speed was not reset correctly after travel when dynamic fan speed was enabled. This caused travel speeds to be used for printing. #10229

- Refactor of export archives for Anycubic Photon Mono and Mono SE printer. Thanks to @Mimoja #9929

- The Ensuring algorithm was filtering perimeters too aggressively causing several issues, including making holes in top surfaces with low inclination (#9978), some bridges not being anchored properly into perimeters (#10231), and non-anchored solid fill when slicing with one top/bottom surface and very low minimal shell thickness. #9988

- Fixed a rare crash in Placeholder parser, when the respective Custom G-code contained specific erroneous syntax. #10183

- The wrong flow was used for spacing of internal bridging over infill causing an error when a small nozzle diameter was used or a small layer height was applied.

- The 'Dynamic overhang speed' feature applied volumetric limits incorrectly for some overhangs. By now for a zero input value, the external perimeter speed is used instead. #10269

- Fixed ‘Bad function call’ without any obvious reason for Organic support. #9892

- Fixed height detection when using sequential printing. #10312

- Linux specific: Fixed object disappearing when opening SLA hollowing or support gizmos.

- The issue of broken object indexing for the 'Label object' feature has been fixed by assigning an incremental index randomly to each object and adding relevant comments, making it easy to cancel objects in OctoPrint and other applications. #10257

- Fixed error when adding instance to a mirrored object.

- When adding an instance use the orientation of the currently selected instance.

- Fixed a crash when sending G-codes to "Mainsail/Fluidd" print host (introduced in 2.6.0-alpha6). #10210

- Resolved the issue where entering too low or too high values for parameters Branch Diameter and Tip Diameter resulted in errors such as "Divided by zero" or caused the software to crash. #10385

- Windows specific: Fixed the issue where disconnecting an SD card that was connected via an external card reader would also disconnect the card reader, requiring it to be disconnected and reconnected to be loaded again. The new code also triggers Windows notifications. #9881

- Fixed the issue where the SLA support gizmo was inactive and was not possible to slice due to invalid data. The issue was triggered by attempting to hollow an object without proper settings.

- Fix of crash upon loading a 3mf project with cut objects. #10319

- Fixed occasional crash in Organic supports. #9665

- Fix an issue where the 'Place on Face' gizmo did not work correctly with instances, causing the marks on the surface to be inactive for added instances.

- Fixed a crash that occurred when an object placed outside of the print bed was arranged. #10241, #10278, #10416

- Fix of crashes in the Support Point and Hollowing gizmos when used with non-printable objects. As a result, SLA supports and Hollow gizmos are now disabled when a non-printable object is selected, and users are prevented from setting an object to non-printable while these features are active.

- Fixed occasional crashes during arrange.

- Resolved issues when rotating individual instances around the X or Y axis (crash on macOS, incorrect selection on Windows and Linux).

- Fixed a bug in the rounded extrusion calculation. This issue caused inconsistent bridge extrusion widths for different 'bridge_flow_ratio' values. #9007

- Fixed a crash that occurred when loa...

PrusaSlicer 2.6.0-alpha6

Summary

This is another alpha release of PrusaSlicer 2.6.0. Among other things, the release adds support for Klipper firmware flavor, extends capabilities of custom G-codes, improves Arrange function, enhances Export to STL to subtract negative meshes, and fixes bugs found in previous alphas. For the full list of new features in the 2.6.0 series, please read the release logs of 2.6.0-alpha2, 2.6.0-alpha3, 2.6.0-alpha4 and 2.6.0-alpha5.

To let you enjoy the alpha without worries, the alpha builds save their profiles into the PrusaSlicer-alpha directory, so you may use the alpha side by side with the current release without ruining your production configuration.

Klipper firmware support #3452

While it has been technically possible to use PrusaSlicer with printers running Klipper even in previous versions, it required the printer profile to be properly set and the settings were not intuitive. To make the configuration easier:

- There is now an extra G-code flavor for Klipper (

Printer Settings->General->Firmware flavor) - The machine limits table is shown to allow more precise time estimates, but no values from the Machine limits table are emitted into the G-code when Klipper is selected

- The automatic insertion of temperature commands at the beginning of the G-code is now optional and is controlled by a new configuration checkbox named "Autoemit temperature commands". If you are using macros in your Start G-code to set temperatures, you might want to turn this off. It is enabled by default to maintain backwards compatibility. #2420, #6847, #10018

- Acceleration can be set separately for travel moves

- There is a new print host named

Mainsail/Fluidd

Placeholder parser improvements

The macro language that is used to process Custom G-codes got several significant improvements, namely:

- Added support for local and global variables #4048 #7196

- Support for "writable" variables, that can be used to pass changes of state (such as position or retraction) that a custom G-code performed back to PrusaSlicer so it knows to compensate.

one_of()function to match an argument to any of the given patternsinterpolate_table()function, which interpolates a piecewise linear function at pointxsize()andempty()functions to return the state of any vector variable- New and simplified syntax for

if-elsif-elseblocks - Added vector placeholders

extruded_volume,extruded_weight,extruded_volume_totalandextruded_weight_totalto give current consumption of the material for individual extruders

The changes are described in more detail in the respective wiki page.

Other improvements with respect to 2.6.0-alpha5

- 'Arrange' and 'Fill bed with instances' functions now take into account skirt and brim separation (#3072, #3477, #5286, #5310, #9301, #9309). Many thanks to @jschuh (#7653) and @individ-divided (#9181), whose pull requests were very useful sources of inspiration, despite not being used verbatim.

- The 'Export as STL/OBJ' function is now able to subtract negative meshes. Note that the algorithm may fail on non-manifold geometries (e.g., those containing self-intersection, etc). In that case, the user is notified, and only positive volumes are exported. #9798 #7594 #8853

- The configuration option

Only infill when neededwas removed. It never worked well, and it was a frequent source of confusion and bug reports when it removed infill from places where it was desirable or vice versa (#9790, #8381, #7914, #6286, #5791, #4916, #2796). The option is superseded by Lightning infill (#8648) and the feature has become too much of a maintenance burden, leading to problems when implementing new features #9935. - The 'Purging volumes' settings accessible by a button in the right panel is now only shown and used for single-extruder multi material printers. Setting purging volumes based on which filament is unloaded does not make sense for proper multi-extruder systems, which can easily control the required purging in

Filament Settings->Advanced->Minimal purge on the wipe tower. Note that this is potentially a breaking change, affecting non-single MM profiles with the 'Purging volumes' set much higher than the value in filament settings, in which case the wipe tower will become smaller than it was in previous PrusaSlicer versions. - The wipe tower can optionally be printed with a "stabilization cone", which prevents it from toppling over. The apex angle of the cone is adjustable in

Print Settings->Multiple Extruders->Wipe tower. Setting the value to zero disables the cone. - The spacing of purging lines on the wipe tower can be increased using another new configuration option in

Print Settings->Multiple Extruders->Wipe tower - The size of the wipe tower preview block the 3D scene should now be more precisely estimated

- When switching to 3D scene after slicing in SLA mode, the pad and support trees are now shown as they were in 2.5.x. This functionality was temporarily removed in 2.6.0-alpha2 because of issues it caused when using negative meshes (which was not possible in 2.5.x).

- Print bed reference axes are now automatically downscaled when zoomed in #9483

- The pointy ends of 'Frustum'-type connectors produced by the Cut tool are now slightly trimmed

- When an edge is selected in the Measurement tool, its length is shown in the measurement dialog

- It is now possible to set separate acceleration for travel moves in

Print Settings->Speed->Acceleration control. The value is clamped by the maximum travel acceleration inPrinter Settings->Machine limitswhen using Marlin 2 or RepRapFirmware flavor. - The

M107(turn fan off) command emitted at the beginning of the G-code was removed - For a long time, PrusaSlicer would scan the Start G-code and insert temperature-setting commands when they were not present. This feature is now optional and is controlled by a new configuration checkbox named "Autoemit temperature commands".

- 'Save/Rename Preset' dialog was simplified when only one preset is being saved/renamed.

- Organic supports: reduced default

support_tree_top_rateto 15% - Estimated print time for the first layer was added as a comment at the end of the G-code, supplementing similar information already available

- The text tool behaves better when positioning text on an object with multiple instances

- The text tool now has a lock switch next to 'Rotation' field in the Advanced controls. This allows to unlock the free rotation. It is for dragging text over the surface without orientation jump.

- Constrained scaling (scaling using the scale tool while pressing the CTRL key) can now be used with any selection

Bugs fixed with respect to 2.6.0-alpha5

- The reference axes at the origin were incorrectly rendered on top of objects when viewed from the bottom of the bed

- Filament type dropdown did not accept user editable text #9770

- Extra perimeters on overhangs were printed in the air when the external perimeters option was enabled #9545

- The cut tool did not place the pins and holes correctly when used on an object with scaling applied #9991, #10010, #10056, #10096, #10126

- Export STL did not export anything when the file extension entered in the Save dialog was not lowercase #10000

- Fixed a hang in rare cases when calculating Organic supports #10048

- The new bridging algorithm that extends bridge infill over sparse infill now works with Adaptive Cubic and Adaptive Support infill types. The only infill type that is not yet supported is Lightning infill.

- The bridge angle setting was incorrectly interpreted as if it was in radians instead of degrees #9963

- Fixed an incorrect bridging angle in some cases #10086, #9895

- The new bridging algorithm generated overextrusions when 'Thick bridges' were enabled #10073

- The new bridging algorithm was extremely slow in certain cases #10049

- The new bridging algorithm sometimes extended the bridging extrusions too much (mentioned in #9245 (comment))

- When 'Disable fan for first N layers' was enabled, the 'Fan speed on overhangs' feature did not work correctly (#9975, thanks @jschuh)

- Fixed a false positive warning about stability issues, sometimes appearing on simple models with straight walls #9744

- Fixed a crash when using add instance function with the wipe tower selected

- Several layout issues were fixed #9768

- It was not possible to export multi-extruder config when some filaments had

idle_temperaturechecked and others did not #10163 - Fixed an error sometimes reported when slicing in SLA mode

- macOS specific: Fixed a crash in the text embossing tool when moving a text with on an object partially below the bed

- Fixed incorrect selection in Object list when moving a part of an object below the bed (or from below the bed)

- Fixed a bug in Organic supports that caused the trees to cut through an object in some cases

- Fixed a hang in the Arachne perimeter generator with specific geometries #10034

- Improved eject function on Windows. Since our code added to 2.6.0-alpha2 is having issues with external SD card readers, we have added a detection of such devices (based on https://github.com/microsoft/Windows-driver-samples/tree/main/usb/usbview). Detected external SD card readers are ejected using the code from 2.5.0 and older. We are aware that the older approach might eject devices too early...

PrusaSlicer 2.5.2

Summary

This is the final release of PrusaSlicer 2.5.2. This release is functionally equivalent to 2.5.1, the only difference is that it contains profiles for Original Prusa MK4 printer.

It does NOT contain Organic supports, the improved Cut tool, and other features introduced in PrusaSlicer 2.6.x series. These are currently only available in 2.6.0 prerelease versions (the most recent currently being 2.6.0-alpha5).

PrusaSlicer 2.5.1

Summary

This is the final release of PrusaSlicer 2.5.1, which is a minor release containing profiles for the Original Prusa XL printer and several related improvements over 2.5.0.

It does NOT contain Organic supports, the improved Cut tool, and other features introduced in PrusaSlicer 2.6.x series. These are currently only available in 2.6.0 prerelease versions (the most recent currently being 2.6.0-alpha5).

Improvements with respect to PrusaSlicer 2.5.0

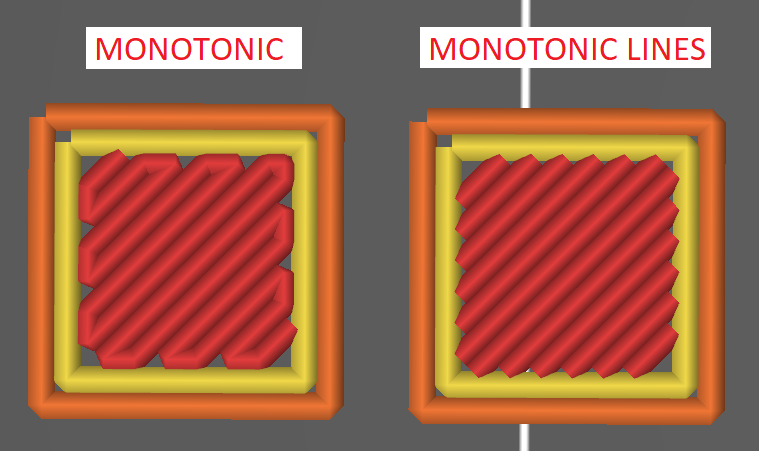

- 'Monotonic lines' top/bottom fill pattern

It is very similar to Monotonic, except that adjacent lines are not connected. This allows for smaller perimeter/infill overlap and results in better filling of the top/bottom layer, less over-extrusion, and better dimensional accuracy.

- It is now possible to set acceleration separately for external perimeters, solid infill and top solid infill (

Print Settings->Speed->Acceleration control) - Original Prusa XL specific: Arrangement into the corner

The Prusa XL printer has a segmented bed, and it is capable of heating just a part of it to lower power consumption. Because the most efficient way of doing this is to start heating at the corner, the Arrange function in PrusaSlicer can now be configured to prefer corners. The setting is available after right-clicking the Arrange icon in the top toolbar and defaults to "Front Left". Auto arrangement is forced when an object is added to an empty print bed.

Bugfixes with respect to PrusaSlicer 2.5.0

- Fixed a crash sometimes occurring when slicing very detailed models #8834

Profiles

- Added Original Prusa XL profiles

Translations

- Updated dictionaries for CS, DE, ES, FR, IT and PL

PrusaSlicer 2.6.0-alpha5

Summary

This is another alpha release of PrusaSlicer 2.6.0. It brings several substantial changes to the slicing core and fixes bugs found in previous alphas. For new features in the 2.6.0 series, please read the release logs of 2.6.0-alpha2, 2.6.0-alpha3 and 2.6.0-alpha4.

To let you enjoy the alpha without worries, the alpha builds save their profiles into the PrusaSlicer-alpha directory, so you may use the alpha side by side with the current release without ruining your production configuration.

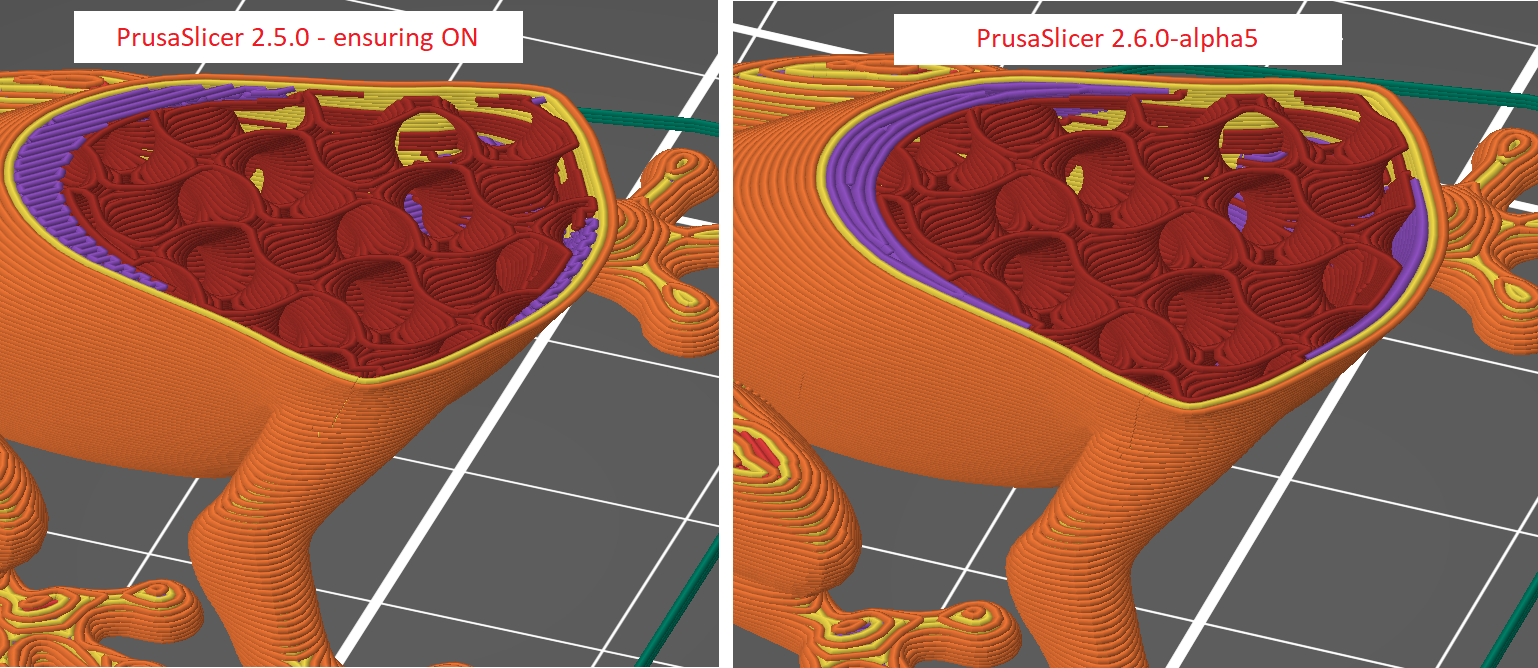

Ensure vertical shell thickness improvement

This change improves one of the most hated feature of PrusaSlicer: too much solid infill and the way it is printed. Some of the related issues are #28, #223, #1054, #1531, #2137, #3744, #6853, #9245, #9898.

The problem and its history are as follows: When printing sloping surfaces, the resulting wall gets thinner (for obvious geometrical reasons). In the case that the slope is small, this effect can even produce holes in these walls, as the external perimeter on one layer may in fact be "more inside" than the innermost perimeter on the layer below. Original Slic3r applied rectilinear infill to fill in these gaps, PrusaSlicer added an extra logic to Ensure vertical shell thickness, which was trying to ensure that the shell would not be thinner than a vertical wall would be. The algorithm had the disadvantage of consuming more material than needed and creating very short segments of infill with abrupt changes of direction, leading to significant vibrations of the printer.

Starting with this version, PrusaSlicer fills the areas with concentric infill. The calculation of the areas is also reworked, so the material is only added where it is really needed. The old "Ensure vertical shell thickness" parameter used to switch between the upstream Slic3r and Slic3r Prusa Edition algorithms to ensure vertical wall thickness. The new algorithm implemented in PrusaSlicer 2.6.0-alpha5 is significantly better than either of the two old algorithms; thus, the switch "Ensure vertical shell thickness" was removed.

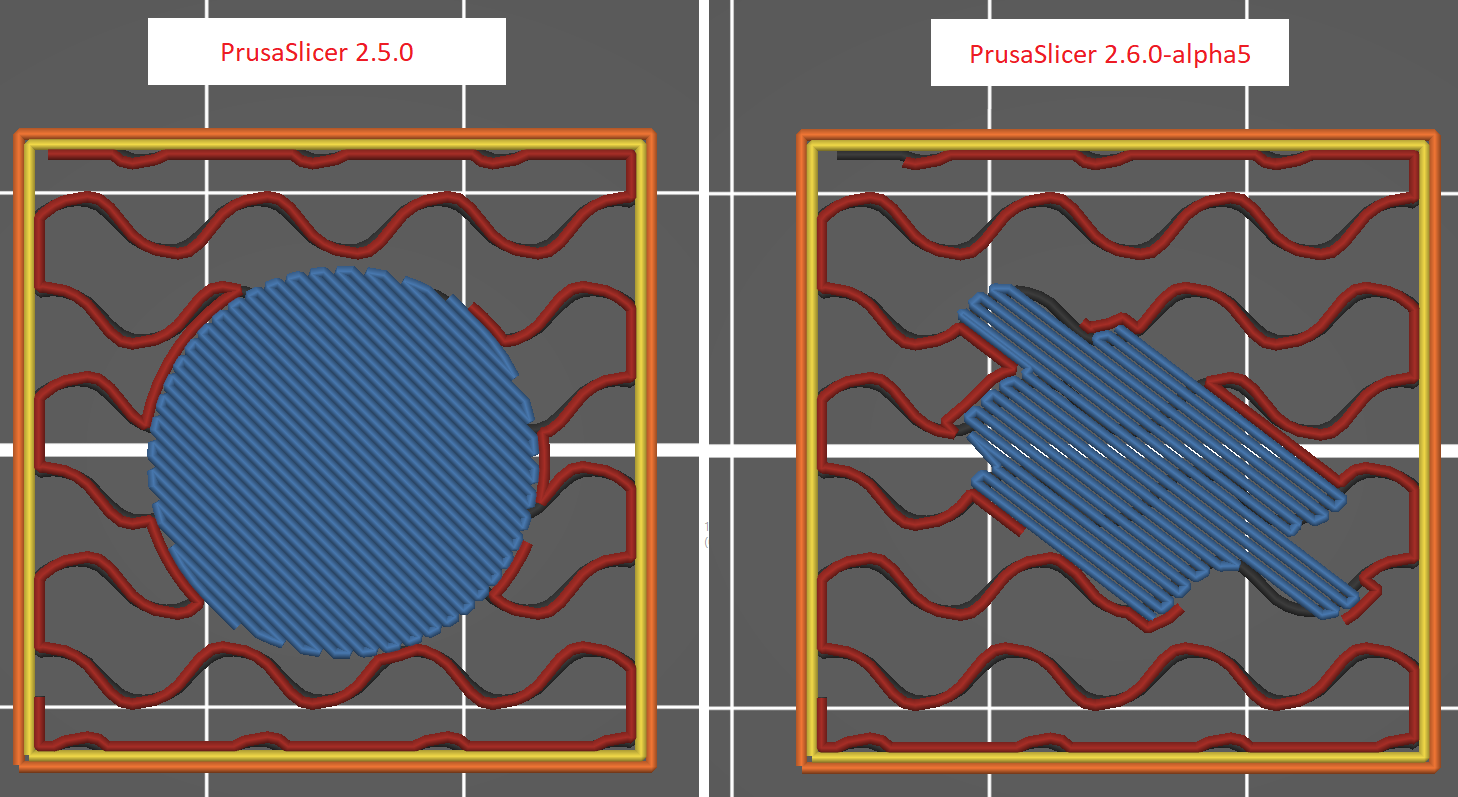

Extend sparse infill #569

Another long-standing issue was connected to bridging solid infill printed over sparse infill. The shape of such infill islands was only determined by what was above, and the infill lines were often inadequately supported as a result, leading to mid-air extrusions and possibly failed prints. PrusaSlicer now extends the lines of the bridge infill so that their ends are supported by the sparse infill on the layer below. The bridge infill is now always using 'Thick bridges'. The new algorithm is NOT applied for Support Cubic, Adaptive Cubic and Lightning infill.

This change also made it possible to decrease the expansion of the bridging layers, which leads to smaller filament consumption and shorter print times. The comparison image below shows exactly the same model (a cube with a counterbored hole in the top face). Only the two adjacent layers are shown for clarity:

Dynamic control of fan speed on overhangs #2921

This feature is similar to Dynamic overhang speed introduced in 2.6.0-alpha2. Fan speed is defined for predefined overlaps, and PrusaSlicer interpolates between the values to set the optimal fan speed when printing overhangs. The feature is accessible in Filament settings->Cooling->Dynamic fan speeds.

Other improvements with respect to 2.6.0-alpha4

- It is now possible to import ZIP file contents from

File->Import->Import ZIP Archive. A dedicated dialog is shown, and the user can select which of the files in the ZIP archive they want to open. - Organic supports can now be used with raft. Raft is built for the object only. Organic supports are routed directly to a print bed, they are not supported by a raft. #9816, #9743, #9526

- Raft interface / contact layers are newly produced with alternating directions, and raft contact layer is newly perpendicular to a fill direction of the first object layer.

- The configuration of

Dynamic overhang speedwas simplified, the percentage levels for which the speeds are set are fixed at 0/25/50/75 %. - There is a new

is_nilfunction available in custom G-Codes to check whether a given configuration option is currently inactive (such as idle_temperature in Filament Settings). Example usage:{if is_nil(idle_temperature[0])}...{else}...{endif}

Bugs fixed with respect to 2.6.0-alpha4

- Wipe tower brim was not shown in the 3D scene after slicing was finished

- Tool temperature visualization in Preview was incorrect in some cases (related to #8324 and #9597)

- macOS specific: Text emboss input dialog did not allow pasting text from the clipboard #9795

- "Avoid crossing curled overhangs" sometimes generated travel moves outside of the bed #9800

- Fixed "Dynamic overhang speed" when Pressure equalizer was used #9485

- Fixed a crash in G-Code Viewer when parsing G-Code generated by Simplify3D #9823

- G-Code Preview did not account for z offset when setting the height of the toolpaths for the purge line in custom start G-Code #9722

- Fixed a crash when trying to add instances when multiple objects are selected #9864

- Various minor improvements and bugfixes in the Cut tool #9771

- Fixed a bug that incorrectly triggered an "out-of-bed" error when specific transformation was applied. The same problem caused issues when changing variable layer height #9467 #9519 #9646

- By pressing the 'T' keyboard shortcut, it was possible to add text to an object that was created by a cut and had connectors. This is now fixed, as this is an unsupported scenario.

- Fixed a crash sometimes occurring on startup on macOS Ventura 13.2.1 #9774

- Reload from disk was not available for 3MF files #9822

- Fixed a crash when cutting an object containing a modifier

Bugs fixed with respect to 2.5.0

- Fixed a crash happening after splitting a painted object into parts (related to all paint-on features). The painting is now removed before the splitting and the user is notified about it #9809

- Fixed missing dense raft layers when number of support top interface layers was set to zero. Mentioned in #7951.

- Fixed discrepancy between the G-code placeholder parser current layer index and the total number of layers. Fixed for non-sequential print only for now #9866

Localizations

- Updated dictionaries for CS (currently incomplete), DE, ES, FR, IT and PL

PrusaSlicer 2.6.0-alpha4

Summary

This is the 3rd public alpha release of PrusaSlicer 2.6.0. It mostly fixes bugs found in previous alphas, but there are also improvements, especially related to the Cut tool. For new features in the 2.6.0 series, please read the release logs of 2.6.0-alpha2 and 2.6.0-alpha3.

To let you enjoy the alpha without worries, the alpha builds save their profiles into PrusaSlicer-alpha directory, so you may use the alpha side by side with the current release without ruining your production configuration.

Cut Tool Improvements

- The Cut tool dialog layout was changed to be easier to comprehend

- Upper and lower part of the object are now highlighted in color

- Added a possibility to cut the object into parts - in that case, connectors cannot be placed and the parts retain its position within the object. Thanks @jschuh for this idea (presented in #9564).

- The controls of the tool obscured the object when it was small #9657

- Added a functionality "Flip cut plane" to easily add pins to the other side of the plane #9632

- The cut tool now works even when the cutting plane does not intersect any volume of the object, so the tool can be used to separate parts into multiple objects without actually cutting anything. This is the same behavior as in 2.5.0. #9629

- When placing connectors in the new Cut tool, the tolerance is now entered in absolute values #9697

- The cut plane is now highlighted on hover, it is newly possible to move it by dragging.

- If the object is cut into parts or when it does not have any connectors, the "lock" of scaling of the resulting parts is not applied #9633

- Performance improvements

Other improvements with respect to 2.6.0-alpha3

- The option "Clip multipart objects" was removed. PrusaSlicer now always behaves as if it was ON. This option was a candidate for removal for a long time, and the new algorithms we implemented for the 2.6 series are no longer compatible with it. We believe that there is really no reason to not clip the objects and we have seen many cases where leaving it OFF accidentally led to unexpected results (overlapping extrusions) #9679, #8779, #3872

- Increased sensitivity of the curled overhang avoidance algorithm

- 'Set Number of Instances' now works when multiple objects are selected #6994

- Organic supports are now consistently referred to as 'Organic'

- Organic supports parameters are now grayed out when different style of supports is selected

- It is newly possible to set acceleration separately for external perimeters, solid infill and top solid infill (

Print Settings->Speed->Acceleration control)

Bugs fixed with respect to 2.6.0-alpha3

- Extra perimeters on overhangs sometimes overlapped with infill #9604

- Fixed an occasional crash when using Organic supports with specific settings #9555

- Fixed a crash during slicing when certain strings were present in custom G-codes. This was also a problem in previous versions, but instead of a crash, incorrect cooling logic might have been applied in these cases #9470, #9550

- The "Export plate as STL including supports" option was grayed out in the menu when the object only had pad and no supports #9558

- Organic supports: All contours are CCW oriented, inner contours are printed before outer contours.

- Fixed crash in Organic supports with a single support layer only #9557

- Linux specific: The new "idle_temperature" option in Filament Settings did not behave correctly when checked and unchecked (UI glitches).

- Fixed a rare crash during slicing with specific geometries #9561, #9562

- "Verbose G-Code" option produced invalid G-Code when "Dynamic overhang speed" was enabled #9588, #9610

- Cooling slowdown was applied incorrectly when "Dynamic overhang speed" was enabled #9594, #9485

- "Dynamic overhang speed" would set speed to zero if the speed was percentage based and external perimeter speed was set to 0 (auto). Thanks @MGunlogson for helpful investigation of this issue in #9622.

- "Dynamic overhang speed" could violate (volumetric) speed limits #9709. Thanks @MGunlogson for helpful investigation of this issue in #9622.

- "Dynamic overhang speed" did not work correctly with Pressure equalizer feature #9485, #9563.

- The "optional" config option

idle_temperaturenow retains its value when disabled and enabled again. If the value cannot be recovered (e.g. after switching to different tab), a value of 30 is used as a default instead of 1500. Previously, the value would change to 1500 (maximum allowed temperature) when the option was reenabled. Same fix was applied to options in Filament Overrides. - When using the Cut tool on a model that was scaled, the manipulation arrows in the scene had incorrect size and the plane was not exactly in its correct position.

- Fixed double-printing of support layers in specific scenarios with soluble supports and interface layers #9647

- Organic support branches sometimes intersected interface layers

- Organic supports did not correctly work when using "Enforce supports for the first N layers" option #9477

- Organic supports did not correctly work when using "Don't support bridges" option #9493

- Various bugfixes and improvements of the Organic supports, thanks @ThomasRahm

- Organic supports ignored overhangs in specific cases, thanks @ThomasRahm #9459

- Fixed missing update of sidebar panel after orienting an object using Place on Face tool

- Experimental option "Wipe tower with no sparse layers" did not work correctly and was causing missing layers in the print #9592 #9703

- The Cut tool could not be applied consecutively when the previous cut placed exactly one connector #9576

- Fix of Physical Printer Dialog: When closing and reopening the dialog, "Host Type" field was incorrectly changed #9695

- The new placeholder

is_extruder_usedintroduced in 2.6.0-alpha2 was not expanded correctly in some cases. - Several issues with object manipulation were fixed (mostly affecting mirrored objects) #9702

- Linux specific: Desktop integration and URL registration are now separated.

- Layout fixes in the Preview dialog when an archive is being opened.

- Fixed freezing during brim generation for specific geometries #9651

- Windows specific: Selected item in Search dialog was unreadable when using dark mode

- The new autopainting of supports did not work correctly when raft was enabled

- Fixed a crash with specific geometries and elephant foot compensation enabled

Bugs fixed with respect to 2.5.0

- Linux specific: desktop integration was failing when

$XDG_DATA_HOMEand$XDG_DATA_DIRSenvironment variables were undefined #9565, #9584 - Windows specific: Fixed UI glitch in PhysicalPrinterDialog when changing the printer selection

- Extruder temperature was occasionally shown incorrectly in Preview when using single extruder multi material #8324, #9597

- Fixed a false positive error report about "Calling AppConfig::save() from a worker thread", appearing when using VM and specific nVidia drivers #7839, #9178, #9370, #9420

Profiles

- Added initial MakerGear bundle (#9169, thanks @Garr-R)

PrusaSlicer 2.6.0-alpha3

Summary

This is the 2nd public alpha release of PrusaSlicer 2.6.0. It mostly fixes the most critical bugs found in previous 2.6.0-alpha2. For new features in the 2.6.0 series, please read the release log of PrusaSlicer 2.6.0-alpha2.

To let you enjoy the alpha without worries, the alpha builds save their profiles into PrusaSlicer-alpha directory, so you may use the alpha side by side with the current release without ruining your production configuration.

Improvements with respect to 2.6.0-alpha2

- Minimal connector size in the Cut tool was reduced to 1 mm #9500

- Icons were added to radio buttons in the Cut tool to make selection of connector type more clear.

- Windows and Linux specific: Downloading from Printables.com requires the user to allow this feature in Preferences for a specific executable. An extra dialog notifying about this is now shown on startup when the new version is first run.

Bugs fixed with respect to 2.6.0-alpha2

- Downloader preferences options were crashing in G-Code Viewer #9496

- Cut function did not correctly apply tolerances to pins and holes #9554

- Fixed unintended path connections in Extra Perimeters when gap fill was applied #9480

- Fixed occasional crashes with specific brim geometries #9513, #9489, #9543

- Fixed crashes of stability alert checker, when empty print object was passed to it

- Fixed occasional crashes when using modifier meshes #9466, #9511, #9518

- Fix of a crash with sequential print and raft #9464, #9509, #9522

- macOS specific: PrusaSlicer 2.6.0-alpha2 has issues starting in certain languages because of locales-related issues. A temporary workaround was implemented and the application now starts with English locales (an error message is shown on startup). The issue is being investigated further #9476

- A validation check was added for scenarios not yet supported in the alpha: Organic supports do not work with variable layer height, Avoid crossing perimeters option and avoid crossing curled overhangs cannot be enabled together #9528

- Contour shown in Cut tool did not show correctly when the model was scaled.

PrusaSlicer 2.6.0-alpha2

Summary

This is the first public alpha release of PrusaSlicer 2.6.0 (alpha1 was not public). It brings the most anticipated Organic supports, measurement tool and text embossing tool. Cut tool now allows orienting the cut plane and adding connectors, there is a possibility to download files directly from Printables.com and several new features were added in order to improve FDM print quality. There are of course many more improvements and bugfixes.

To let you enjoy the alpha without worries, the alpha builds save their profiles into PrusaSlicer-alpha directory, so you may use the alpha side by side with the current release without ruining your production configuration.

Github clips this text at the release history overview. Please open the 2.6.0-alpha2 release log to see the complete change log.

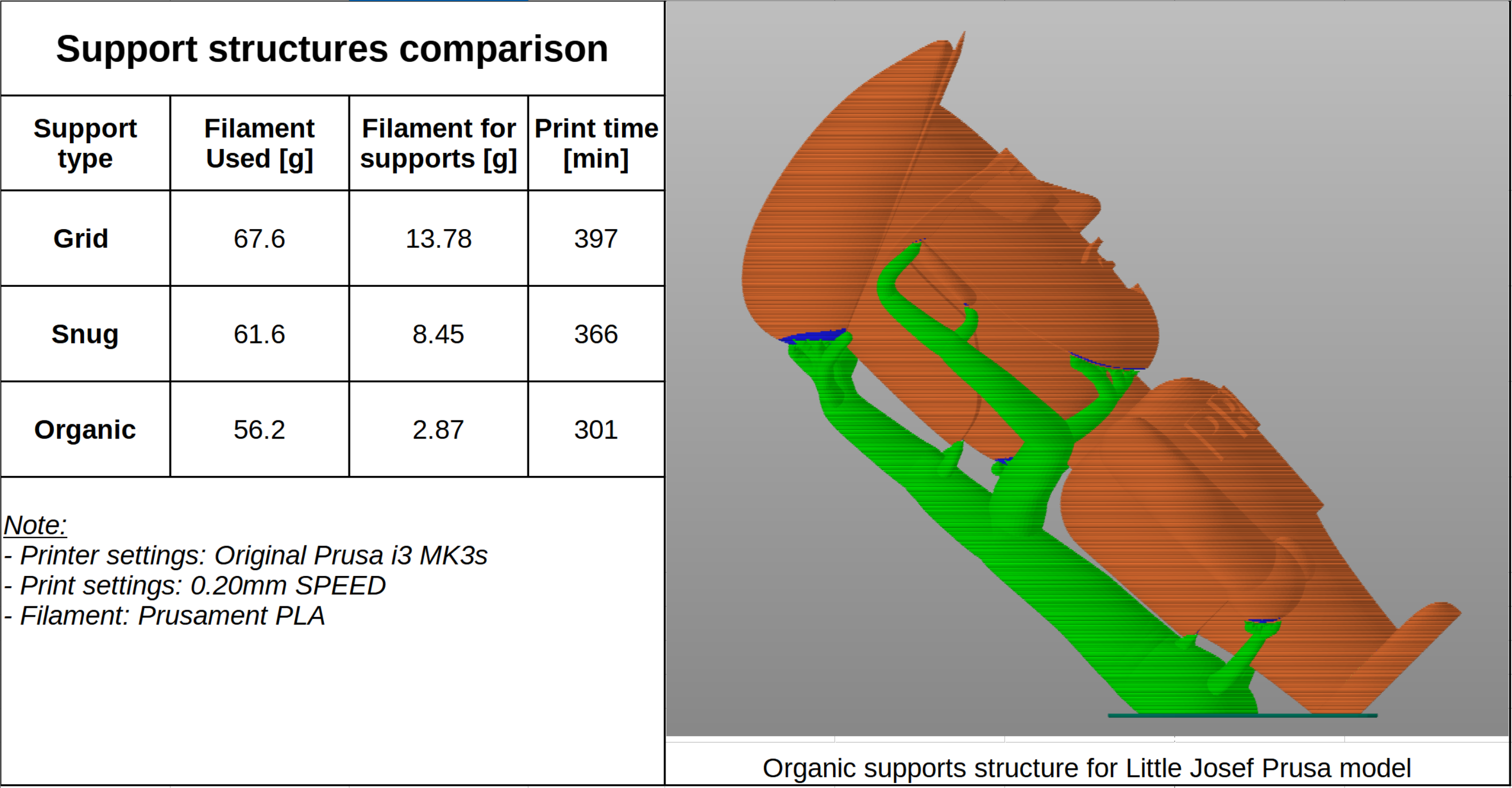

Organic supports #1514

Until now, PrusaSlicer's supports consisted of 2D "scaffolding" created on a regular 2D grid. While the approach produced reasonably good results in many cases, they often consumed quite a lot of filament, took a long time to print, ended up in spaces where they are difficult to remove from and left visible scars on the model when removed (especially when the settings were not tuned correctly). We improved some of these downsides by introducing the "Snug" supports in PrusaSlicer 2.4.0, but they are still an upgraded version of the old and limited approach.

An alternative approach, which was pioneered by different 3D modeling softwares and slicers are "Tree supports" - support structures designed to save material and printing time as much as possible. Branches of supports are generated where needed and limit contact areas to a necessary minimum. This results in a better surface of the original model. The community has rightfully complained that not having this style of supports in PrusaSlicer is a severe disadvantage.

In this release, we are presenting our implementation of tree supports, which we decided to call 'Organic supports' because of their smooth shape. The algorithm is based on @ThomasRahm 's implementation of tree supports, which are significantly improved tree supports originally from Cura. We would like to thank Ultimaker Cura and @ThomasRahm (see his Reddit post) for the effort they have invested into the problem.

The supports are easily removable, do not scar the surface and are fast and cheap to print. The algorithm automatically uses double perimeter walls for the trees where needed to improve structural capabilities. Like other support types implemented in PrusaSlicer, Organic supports can be enforced or blocked using the Paint-on supports tool.

We recommend to use the Organic supports together with the following two new features (see their respective sections below):

- Automatic FDM support painter produces the right amount of supports for sufficient model stability.

- Avoid crossing curled overhangs reduces risk of print head kicking the model and angled tree supports off the build plate.

The Organic supports currently pose the following limitations:

- For large models with a lot of supports, 16GB RAM minimum is recommended.

- Top / bottom vertical separation distances are rounded to multiples of layer height.

- Variable layer height is not supported.

- Interface layers are not always produced reliably. As of now printing with zero interface layers is recommended, which produces easy to remove supports.

- Rafts with Organic supports are buggy.

Measurement tool #3651

Measurement tool is another feature long demanded by our community. The tool utilizes a geometry detection algorithm that recognizes points (vertices), edges, circles and planes. Users can check model sizes and angles directly in the slicer, so there is no need to open 3rd party software anymore for this purpose. At the moment, it is possible to measure between parts to simplify their better manipulation and organization inside objects (but not between separate objects). Last but not least, the tool allows to uniformly scale the object to the required length by clicking a button in the scene.

One of the current limitations of this tool is its behavior on objects with overlapping parts. In such cases, the parts are considered individually, meaning that edges created by the intersections are not detected, and planes hidden inside other parts are. The tool also does not work well with negative volumes, which are considered as parts.

Text embossing tool

This tool opens a new capability to insert, manipulate and edit text created like a new volume of an object. It allows to add notes, signs, serial numbers, etc. directly in the slicer.

The text can be placed on any type of surface, not only a planar one. There is an option to "Use a surface", which forces the text to follow the parent object surface along the whole text length. Text manipulation can be simply performed by dragging text around the object to be placed in the desired position. There are also possibilities to rotate (Z-rot) and elevate (Z-move) text directly in the Emboss panel.

The text editor automatically imports fonts from the user's system library. Basic or advanced properties of text are available to change and edit. Final text volume can be used like any of the usual types: part, negative volume or a modifier. The whole project with text entities is saved to 3mf and after reopening, the text is fully editable.

How to use: right-click the object and choose Add part->Text.

Functionality overview:

- Insert and manipulate text volumes

- Recognize and import the user’s font library

- Edit text in many different ways

- Create, save or delete text style

- Set type of text volume – object part, negative volume, modifier

- Use Surface mode to project text on an object's surface

- Editing the text at any time, not only when created

Cut tool update

The Planar Cut tool has been available in PrusaSlicer for a long time. It is handy for preprocessing huge models that don't fit the build volume, are too complicated to print in one piece, or models where only a part is valuable for the user. With this release, we decided to extend its functionality.

The model can newly be cut by a generally oriented plane (#4368, #5706). For cut plane manipulation purposes, the tool enables movement and rotation to an appropriate position. Z positioning is also possible to manage by numerical input value [mm]. Rotation around the X and Y axis is set up by a gizmo enhanced with 5 degrees snipping ability. Alternatively, the plane could be defined by selecting two points on an object or in space around it. To use this feature, press Shift and draw the requested cutting plane in the scene using the left mouse button.

Also, we understand how important it is for users to assemble final parts to a single object with an emphasis on precision and simplicity. That's why we added an option to define various types of connectors (#803, #8656, #5553, #1857). The user can enter editing mode for placing the connectors by pressing a button in the Cut panel. There are several shapes and styles of connectors to choose from. Users can also control the depth, size, and tolerances of each connector member and negative hole.

"Lay down" options help automatically place removed parts straight after the cut performs (#3154).

After the cut is performed, the resulting objects "remember" that they belong together and certain operations are not permitted. For example, one cannot scale one object and not the other, as that would make the parts not match. The information is visible in the Object List and is also saved into a 3MF. It is of course possible to break this correspondence and manipulate the objects without limitations.

Automatic FDM support painter and print checker

For a long time, PrusaSlicer allows the user to paint areas to be supported. This is a much praised feature that allows the user to customize supports quickly and easily. As part of a large effort to create more intelligent support creation, the FDM support painting tool now contains an option for automatic painting of enforcers on the model. The algorithm behind this tool checks the print extrusion by extrusion and takes into account many factors such as the center of mass, weight of the supported part, bed movement, potential extruder collision, bed adhesion, material, and bridging. The result should be more effective support placement. For example, bridges are supported only on regularly spaced pillars and not over their full length.

The tool is also executed during slicing, providing conservative warnings in case no supports are to be generated but most likely some supports are needed. Experts may find such warning obtrusive, thus the warning may be disabled in application preferences.

Dynamic overhang speed #9348

Dynamic overhang speed functionality enables reliable slowdown of overhang extrusions. Lower velocity enables...

PrusaSlicer 2.5.0

Summary

This is final release of PrusaSlicer 2.5.0, introducing Arachne perimeter generator, Lightning infill, Pressure equalizer, STEP file import and various smaller features and bugfixes. The final release fixes a single bug found in PrusaSlicer 2.5.0-rc2. See the release logs of 2.5.0-alpha2, 2.5.0-alpha3, 2.5.0-beta1, 2.5.0-rc1 and 2.5.0-rc2 for the complete list of changes with respect to 2.4.2.

Bugfixes with respect to PrusaSlicer 2.5.0-rc2

- Fixed seam-like artifact visible on certain models when using Arachne perimeter generator and Fuzzy Skin feature #8793

Translations

- Updated translations

- Updated Catalan translation (#8787, thanks @davidjuanesb)

PrusaSlicer 2.5.0-rc2

PrusaSlicer 2.5.0-rc2

PrusaSlicer 2.5.0-rc2

Summary

This is second release candidate of PrusaSlicer 2.5.0, fixing bugs found in PrusaSlicer 2.5.0-rc1. See the release logs of 2.5.0-alpha2, 2.5.0-alpha3, 2.5.0-beta1 and 2.5.0-rc1 for the complete list of changes with respect to 2.4.2.

Changes with respect to 2.5.0-rc1

- We added filament type "PA" into the list in Filament Settings #8713

- Seam enforced areas were not always respected with Arachne perimeter generator #8695

- Fixed crashes in Arachne perimeter generator happening for specific geometries #8724, #8747, #8753, #8761

- Fixed artifacts produced by Arachne perimeter generator in specific cases #8778, #8760, #8742

- Post-processing scripts on macOS and Linux were not executed when

$SHELLenvironment variable was undefined #8766

Localization

Profiles

- Added Creality Ender-3 Neo and Ender-3 S1 Plus profiles (#8746, thanks @pmjdebruijn)