-

Notifications

You must be signed in to change notification settings - Fork 248

Shipment and Order Management

MSI supports order management through Magento to update inventory for invoices, shipments, refunds, and cancellations. The following information details how to use the Source Selection Algorithm(SSA) for shipment recommendations and processes for managing and shipping your orders.

- MSI supported orders

- SSA at Shipment

- Rerun SSA and ship

- Override SSA recommendations and ship

- Refund orders and update inventory

- Cancel unshipped orders

For additional information on order management including processing orders, invoices, and shipments, see the Magento User Guide.

MSI supports single orders and multiaddress orders without additional configurations, out-of-the-box. As customers or your staff enter orders, MSI tracks inventory using reservations against the salable quantity, deducting from inventory quantity when invoicing and shipping the products.

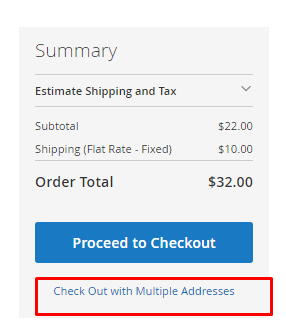

For multiaddress orders, a series of single orders are generated in Magento grouped according to the multiple destination addresses. During checkout, customers select each set of products associated per address during checkout generates as single orders according to the destination address. Each order includes the products associated per address.

|

|---|

| Multi Address Shipping - MultiShipping |

MSI manages inventory for these multiaddress orders exactly like single orders, allowing for SSA or overrides during shipment, partial shipments, canceling orders, and refunding with stock updates. See the following sections for details.

The Source Selection Algorithm provides recommendations for your shipments. You can access the SSA when creating shipment invoices for an order. Through the SSA, you can run the algorithm at any time to determine the best options for matching ordered quantities and available sources.

To complete and ship an order, it must have completed payment and be invoiced. At this time, you can rerun the SSA and ship, or override the SSA options and manually set the sources and quantities to fulfill shipment.

- We recommend rerunning the SSA to review recommendations.

- If you want to change the selections, you can override with manual source deductions.

- You should use the override option when shipping a partial order, completing the rest of the shipment at a later date.

Before proceeding to shipment, you should rerun the SSA. You can run the algorithm and complete shipping for entire orders or partially for sending smaller amounts over many shipments. If you manually change the deductions and rerun SSA, it clears your changes and presents the latest best matches according to the algorithm.

When you rerun SSA, it checks the current quantities per source, weighing the best deductions in inventory quantities based on the selected algorithm. The initial SSA algorithm determines shipments based on source priority configured on the stock. Additional algorithms will be available in later releases, or through custom code and extensions.

Note: Ensure the order has completed payment and is invoiced prior to shipping.

-

On the Admin sidebar, tap Sales. Then, choose Orders.

-

Tap the View link for an active order (or your test order).

-

Tap Ship on the upper menu bar. The ordered products, quantities, sources, and SSA options display.

Source Selection Shipment in an Order -

Tap Source Selection Algorithm to rerun and review recommendations. At this time, the down-arrow offers Source Priority, recommending shipment according to the source priority list per stock.

Later releases will include additional algorithm options in the drop-arrow list.

Later releases will include additional algorithm options in the drop-arrow list.

Source Selection Rerun SSA -

The Items Ordered table updates with recommended amounts to deduct.

-

For the Select a Source to Ship from, select a Source from the drop-down menu matching the recommendation.

-

Tap Proceed to Shipment. Review and complete shipment. The Inventory section displays the source, products shipping, total ordered quantity, and quantity to ship.

MSI Shipping Inventory information -

Tap Submit Shipment to complete.

If not enough products are available from one source, you will need to repeat this process to ship additional products per source. As you enter additional shipments, the information includes the current total shipped.

|

|---|

| MSI Shipping Inventory information for multiple shipments |

You can manually override and set each source and quantity of products in an order directly through the Ship option. This option is helpful when you want to control every product deduction or when fulfilling partial shipments.

When selected, the Source Selection page displays options for selecting a source to ship from, the ordered quantity of product(s), and the currently available sources and salable quantities. Customers are not charged additional amounts when you override and modify quantities per source.

Note: Ensure the order has completed payment and is invoiced prior to shipping.

-

On the Admin sidebar, tap Sales. Then, choose Orders.

-

Tap the View link for an active order (or your test order).

-

Tap Ship on the upper menu bar. The ordered products, quantities, sources, and SSA options display.

Source Selection Shipment in an Order -

For the Select a Source to Ship from, select a Source from the drop-down menu. The Qty to Deduct field is enabled to enter the amount to ship.

For this example, the Texas Warehouse is selected with 20 entered. To keep an on-hand quantity, this could be changed to 10 and another warehouse selected to fulfill the order.

Quantities Selected per Source -

Tap Proceed to Shipment to initiate shipping. This overrides the SSA recommendations. The inventory reservations convert to quantity deductions against the selected sources.

-

Review and complete shipment. The Inventory section displays the source, products shipping, total ordered quantity, and quantity to ship.

MSI Shipping Inventory information -

Tap Submit Shipment to complete.

If not enough products are available from one source, you will need to repeat this process to ship additional products per source. As you enter additional shipments, the information includes the current total shipped.

|

|---|

| MSI Shipping Inventory information for multiple shipments |

Note: This information is being revised/in-progress!

You can refund orders (via a credit memo), either in full or in part. For more information on refund credit memos, see the Magento User Guide.

After the order is refunded, enter another credit memo to return the product quantity to the originating source:

-

On the Admin sidebar tap Sales. Then, choose Orders.

-

Find the completed order in the grid. Then in the Action column, click the View link to open the order.

-

In the button bar at the top of the page, tap Credit Memo. The button appears only after an order is invoiced.

-

Complete any additions and changes needed for handling refunds in your business.

-

Tap the Return to Stock checkbox. The product quantity will return to the specific source. For example, if the product came from a warehouse in New York, the quantity adds back to that source.

-

Complete the credit memo. You can verify the update in stock through the product page.

If an order has not been shipped and is cancelled, MSI automatically returns the product stock to the salable quantity. Until invoice and shipping, purchased products are reserved against the salable quantity, not deducted from the actual quantity. Invoicing and shipping converts the reservation to an inventory deduction.

Behind the scenes, MSI automatically enters a compensation reservation removing the hold on the product quantity. The quantity returns to the aggregated virtual salable quantity.

Multi-Source Inventory developed by Magento 2 Community

- Technical Vision. Catalog Inventory

- Installation Guide

- List of Inventory APIs and their legacy analogs

- MSI Roadmap

- Known Issues in Order Lifecycle

- MSI User Guide

- 2.3 LIVE User Guide

- MSI Release Notes and Installation

- Overview

- Get Started with MSI

- MSI features and processes

- Global and Product Settings

- Configure Source Selection Algorithm

- Create Sources

- Create Stock

- Assign Inventory and Product Notifications

- Configure MSI backorders

- MSI Import and Export Product Data

- Mass Action Tool

- Shipment and Order Management

- CLI reference

- Reports and MSI

- MSI FAQs

- DevDocs Documentation

- Manage Inventory Management Modules (install/upgrade info)

- Inventory Management

- Reservations

- Inventory CLI reference

- Inventory API reference

- Inventory In-Store Pickup API reference

- Order Processing with Inventory Management

- Managing sources

- Managing stocks

- Link and unlink stocks and sources

- Manage source items

- Perform bulk actions

- Manage Low-Quantity Notifications

- Check salable quantities

- Manage source selection algorithms

- User Stories

- Support of Store Pickup for MSI

- Product list assignment per Source

- Source assignment per Product

- Stocks to Sales Channel Mapping

- Adapt Product Import/Export to support multi Sourcing

- Introduce SourceCode attribute for Source and SourceItem entities

- Assign Source Selector for Processing of Returns Credit Memo

- User Scenarios:

- Technical Designs:

- Module Structure in MSI

- When should an interface go into the Model directory and when should it go in the Api directory?

- Source and Stock Item configuration Design and DB structure

- Stock and Source Configuration design

- Open Technical Questions

- Inconsistent saving of Stock Data

- Source API

- Source WebAPI

- Sources to Sales Channels mapping

- Service Contracts MSI

- Salable Quantity Calculation and Mechanism of Reservations

- StockItem indexation

- Web API and How To cover them with Functional Testing

- Source Selection Algorithms

- Validation of Domain Entities

- PHP 7 Syntax usage for Magento contribution

- The first step towards pre generated IDs. And how this will improve your Integration tests

- The Concept of Default Source and Domain Driven Design

- Extension Point of Product Import/Export

- Source Selection Algorithm

- SourceItem Entity Extension

- Design Document for changing SerializerInterface

- Stock Management for Order Cancelation

- Admin UI

- MFTF Extension Tests

- Weekly MSI Demos

- Tutorials